Customer: Montana Furniture

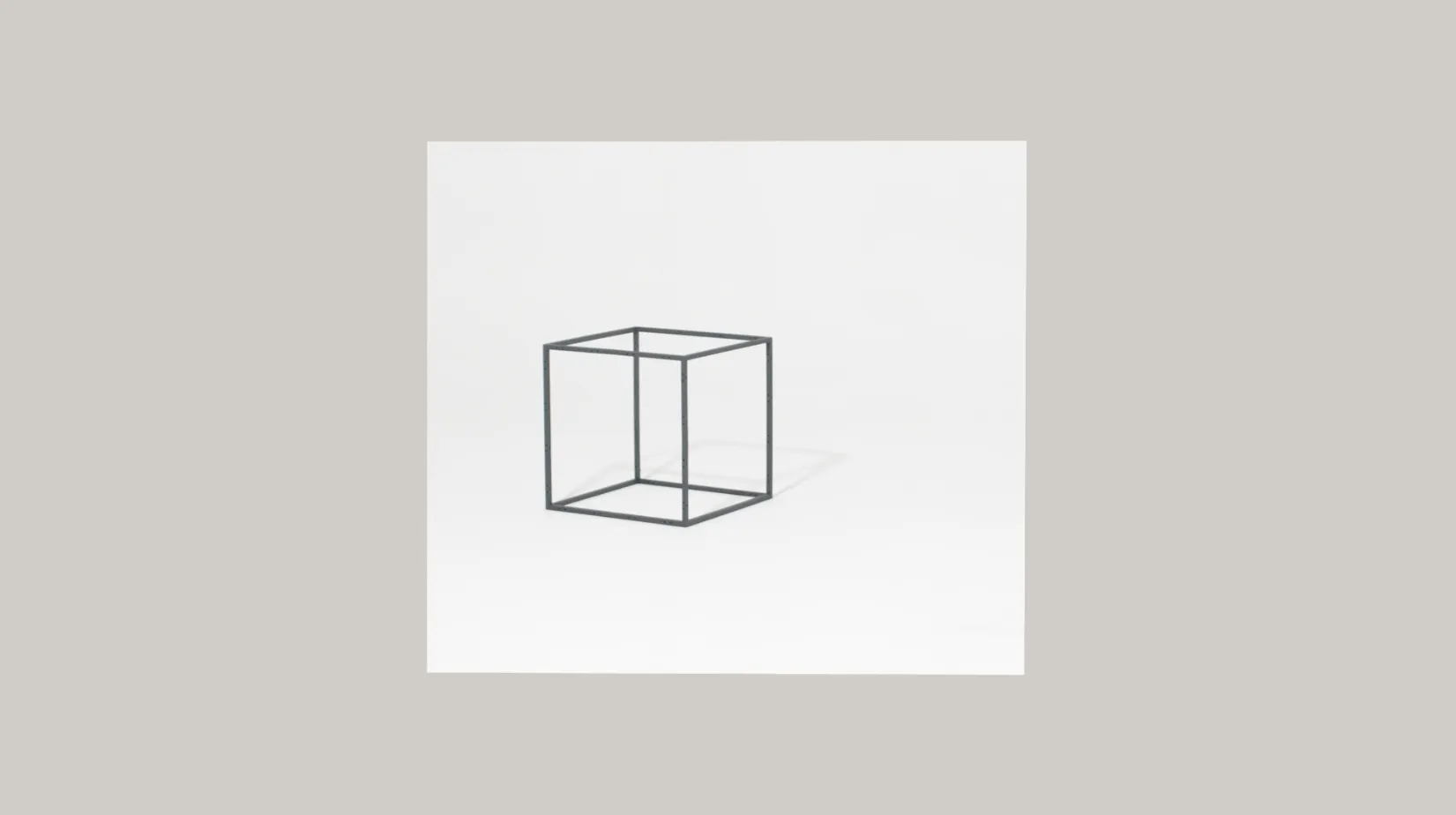

Product: GRID module - injection molded nylon cube

Size: 400 × 400 × 400 mm

Materials: Recycled nylon, glass-filled nylon, fire retardant nylon

Process: Injection molding with robot, mold flow and automatic grinder system

The challenge

Peter Lassen, founder of Montana, had been looking for a European supplier for a long time to realize his vision: a precise and durable plastic cube-shaped module - known as Montana Grid. Many potential partners rejected the project as technically impossible. When he came to Antex Plast, we didn't see problems - we saw opportunities.

The solution

Montana had prepared a metal prototype, which became the starting point for development. Our tooling experts made extensive calculations and combined mold flow simulations with the shrink percentage of the plastic to ensure the final cube was right-angled and easy to demould. We developed a tool and started production with full automation - including robotic operation and an internal granule grinder, which makes it possible to reuse inlets directly without drying. This saves energy and reduces CO₂ emissions.

The result

After just 6 months, GRID was in production in Ulstrup - much to the delight of the customer, who had been rejected all over Europe. Today, Montana Grid is still produced at Antex Plast - now in several variants and material types. The demands on the product have grown over time, and we have continuously adapted production to meet both Montana's and Europe's requirements for sustainability, fire approvals and dimensional stability.

Montana's original GRID now has a "little sister" in the 400 × 400 × 200 mm size, further expanding the design possibilities.

Quote

"It's remarkable that a project that so many thought was impossible could be realized locally in Denmark - and in such high quality."